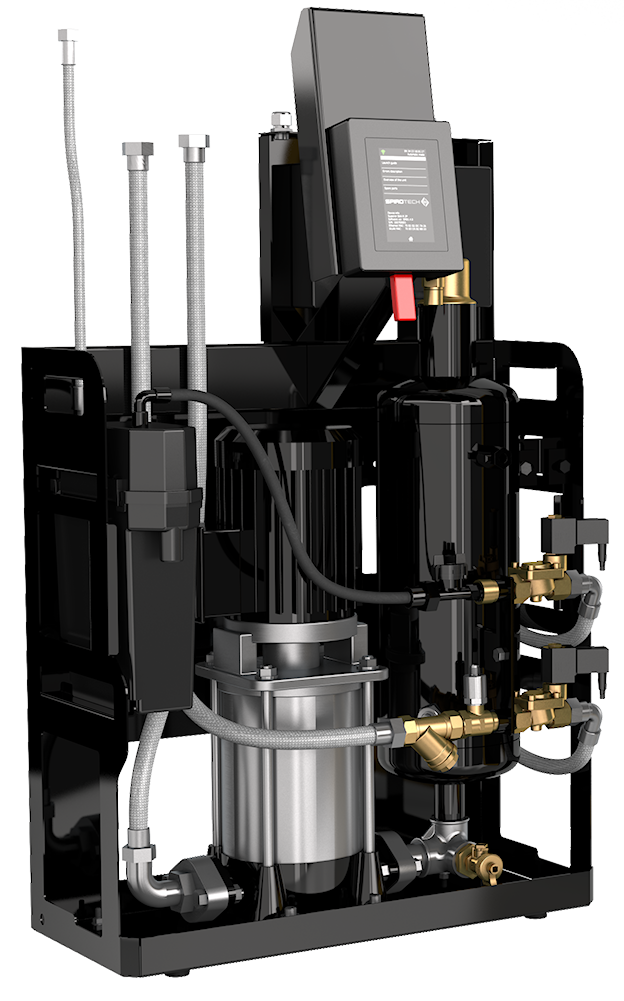

High-Efficiency Vacuum Degassing

Air trapped in fluid systems causes decreased efficiency, excessive wear, and requires more frequent service. Symptoms of this condition are corrosion, noisy operation and fluctuating pressure readings. Ultimately, this leads to damage of expensive system components, system malfunctions or even complete failure. Proper air separation is the only effective method of eliminating these issues.

Removing Gases From An Installation

There are two methods for extracting and removing gases from heating, cooling or process water systems.

Passive degassing: By using inherit temperature and pressure differences that exist within the system, dissolved gases are naturally released. With a Spirovent coalescing air separator, such released gases can be extracted from the liquid. This requires the air separator to be installed at the place of lowest solubility (lowest pressure/highest temperature).

Active degassing (Vacuum Degassing): By actively creating a pressure change such that a portion of the system fluid is temporarily placed in a state of negative pressure (vacuum). The gases dissolved in the fluid are released, separated and removed from the fluid. The treated fluid can then reabsorb air from the system for subsequent removal.

When Does Vacuum Degassing Make Sense?

- An inline air separator cannot be installed at the desired location or only at excessive cost.

- In systems with many branches and partially low flow rates. Free collected air may not be carried to the air separator due to the low flow rates.

- Eliminate air from make-up water before it is introduced into the system.

- Systems with significant elevation differences (e.g. multi-story buildings)

View/download product brochure.

|

|

Product Summary

- Unsurpassed efficiency

- Easy installation, just two 3/4" connections

- System volume up to 80,000 gallons per unit

- Optional make-up water feature

- Quiet operation