After having tried numerous other methods, the first Spirovent was installed in Carman Hall to deal with a long history of no heat calls and clogging valves. The very next season resulted in almost no calls or valve issues in this two-pipe high-rise residence hall. Since then almost all residence halls have Spirovents installed as well as academic buildings and the central loop.

Excerpts from a nationally published case history...

Carman Hall was considered the “problem child” by the campus maintenance staff. The students residing in the 30-year-old twin-tower high rise in the far southeast corner of the campus averaged two to three calls per day complaining about the lack of heat. The record, though, was more than 25 calls in one weekend. Carman Hall is heated using a two-pipe system that takes steam from the central plant and converts it to hot water.

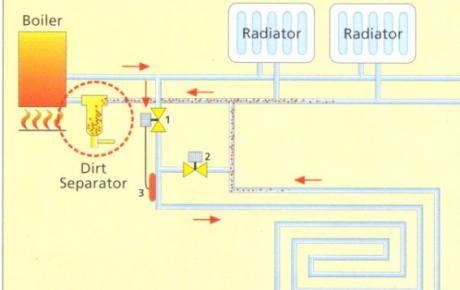

The Spirovent, made by Spirotherm, Inc. (Glendale Heights, IL), employs the patented Spirotube® coalescing/barrier medium to scrub air and dirt from hot and chilled water systems with unprecedented efficiency. The air is released from the top of the unit via a patented air release mechanism, while the dirt falls to the bottom and collects in the dirt chamber where it can be blown down through a manual or automatic blow down valve.

Because Spirovent units are so simple to install, there was no reason to hire a contractor, and the maintenance staff did the installation. EIU states that there has been a definite improvement in system performance since the Spirovent was installed. The valve clogging problems have been virtually eliminated and the no-heat calls have all but disappeared. “The product speaks for itself,” he says. Rick Bagwell, the Environmental Control Foreman at the time, remarks, “I’m very happy with the Spirovents and what they can do. I was skeptical at first because we’ve tried many things and none of them worked. Spirovents are the first that did.”

Since that time, EIU has installed Spirovent combination air and dirt separators in several other buildings and on the central chilled water loops. They tried the product because they were impressed with the demo, but continues to use the product because, in his words, “The Spirovent relieves us of the worry of providing comfort.” As for the bottom line, Spirovent can help with that, too. The savings in man-hours alone in a large university with multiple Spirovents can translate to thousands of dollars per year. Pumps are able to operate more efficiently and no longer waste energy pumping entrained air and dirt. And, those who see a decrease in their chemical treatments realize an even larger savings.